Build with ByBlock — Faster, Cleaner and Greener

Construction Blocks Made of 100% Plastic Waste

ByBlock helps you build faster, cleaner, and greener than any construction block on the market. Made of recycled and often unrecyclable plastic waste, ByBlock gives builders, architects, weekend warriors, and DIY’ers alike a sustainable, high-performing construction material usable for anything from walls to sheds and furniture to fencing.

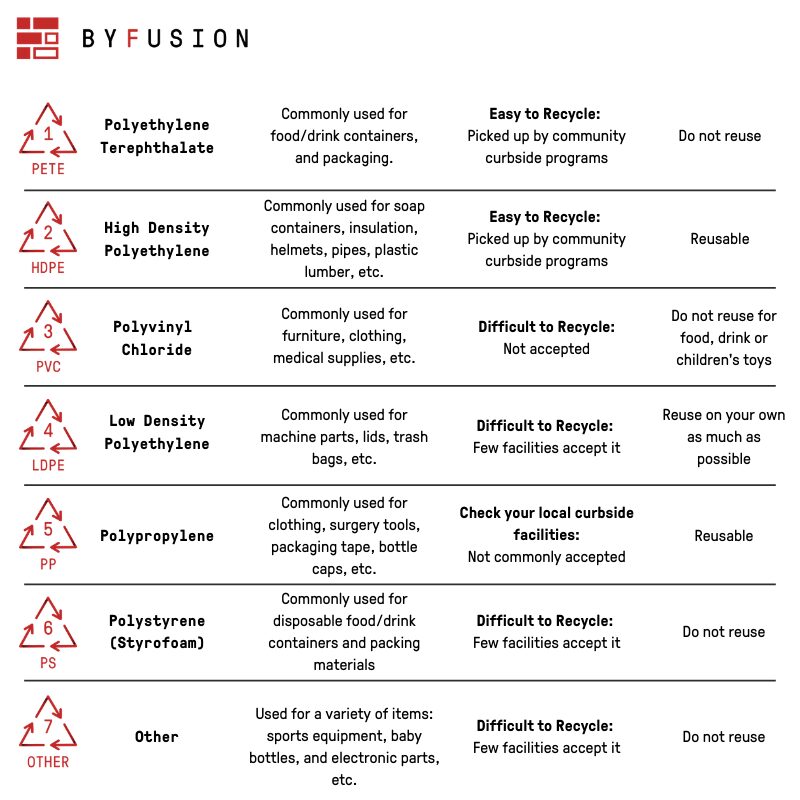

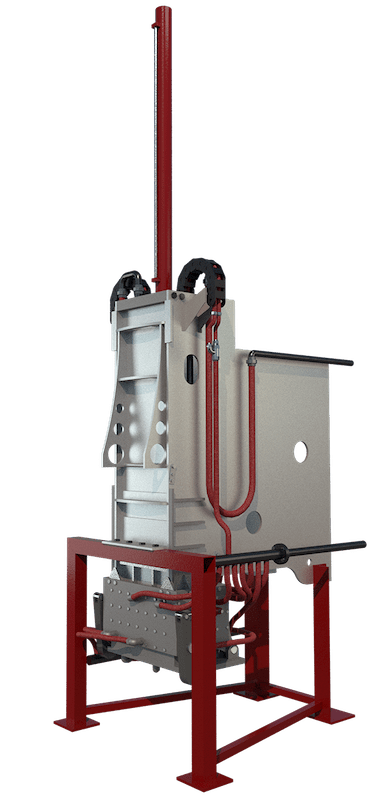

The qualities that make plastic such a valuable material for packaging are exactly what make it one of the most powerful building materials around: it’s malleable, insulative, and doesn’t degrade easily. Using our proprietary system which uses only steam and compression, ByFusion’s clean technology maximizes these traits by processing recovered plastic waste of any sort into ready-made building materials, thus offering builders around the world an easy-to-use, eco-friendly, and inexpensive product to use in residential or commercial settings.

ByFusion’s ByBlock offers one of the most intriguing construction products the building industry has seen in years. Below, we show you how easy it is to build with ByBlock, and hopefully inspire some ideas for what YOU will build with ByBlock.

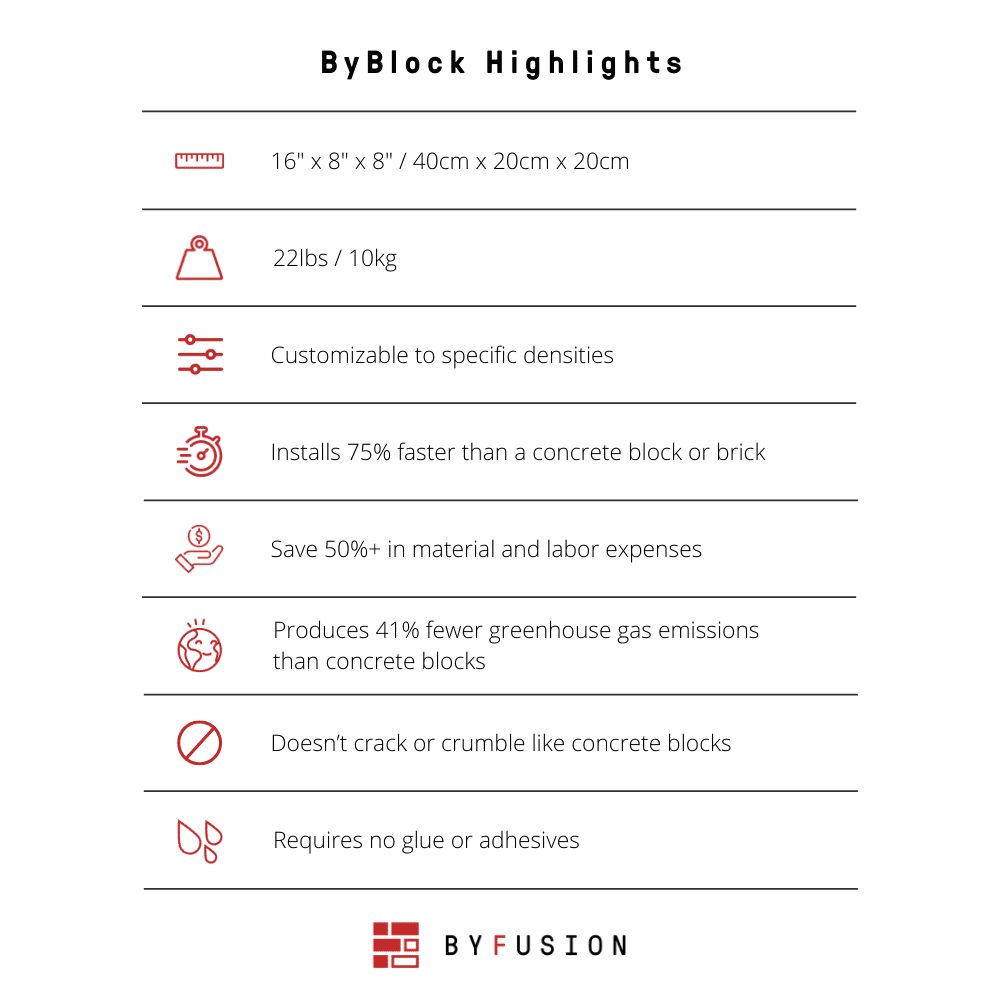

ByBlock Highlights

ByBlock is similar in dimension to standard concrete cinder blocks (CMU) — approximately 16” wide, 8” deep, and 8” tall. Although they are made from 100% plastic waste, their strength is not to be underestimated. Weighing 22 lbs per block, your structure will be sturdy, reliable, and incredibly well insulated.

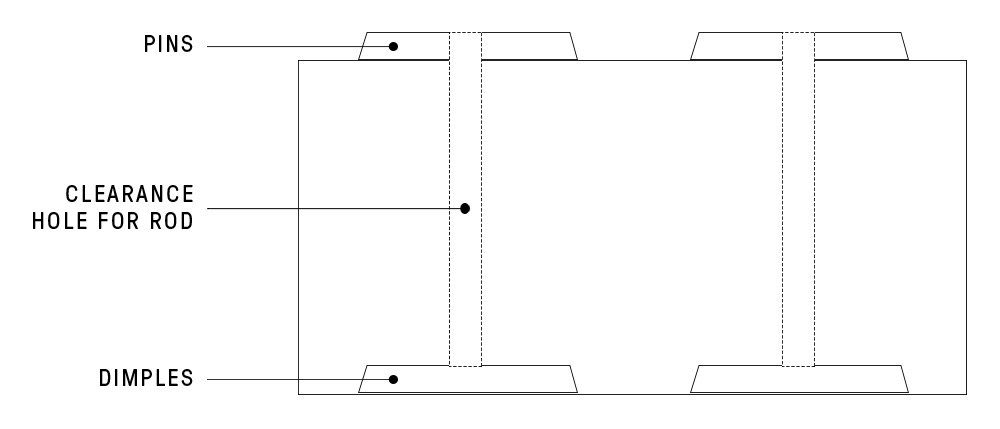

Each ByBlock has two clearance holes (both extending completely through the product), two pins located on the top, and two dimples located on the bottom. The clearance holes are used to run metal rods through each ByBlock to reinforce structure strength, while the pins and dimples are designed to connect to one another while stacking ByBlock (yes — just like Lego).

Want more details on ByBlock? Review this data sheet.

ByBlock’s user-friendly build, coupled with its eco-friendly footprint, make it a unique building material compared to traditional construction materials. But don’t just take our word for it — sustainable builder and ByFusion advocate, Rob Brower, has positive things to say after spearheading the installation of our latest pilot project at the Island School in Lihue, Kauai.

“The ByBlocks went up fast and easy. When you see how the finished product looks, it’s clear that ByBlock is a great way to give plastic waste a responsible end use. They seem to have great R value and sound proofing qualities.” — Rob Brower

So, ByBlock saves you time, money, and energy — but we’re sure you still have a few questions. Here are some frequently asked questions:

What about the potential of pesky termites and water damage?

ByBlock’s plastic composition renders it both insect- and water-proof. In fact, because plastic does not absorb moisture, ByBlock will actually float!

What if I move and want to take my ByBlock structure with me?

Any project made from ByBlock can be disassembled and repurposed (with the same strength and quality) easier than any other building material. ByBlock will not crack under pressure nor break if dropped, so you don’t have to worry about replacing materials. If you do somehow manage to break a ByBlock (a feat we have not found to be easy), any waste material can always be sent back and remade into a new fully functioning ByBlock.

Does ByBlock contribute to LEED certification?

Yes - ByBlock will contribute to LEED credits. Our low emission process, high rate of plastic waste diversion, and minimal materials required for installation make ByBlock the most eco-friendly building block to choose from.

Now that you know ByBlock’s benefits compared to traditional building materials, put on your hardhat and let’s dive into the building process.

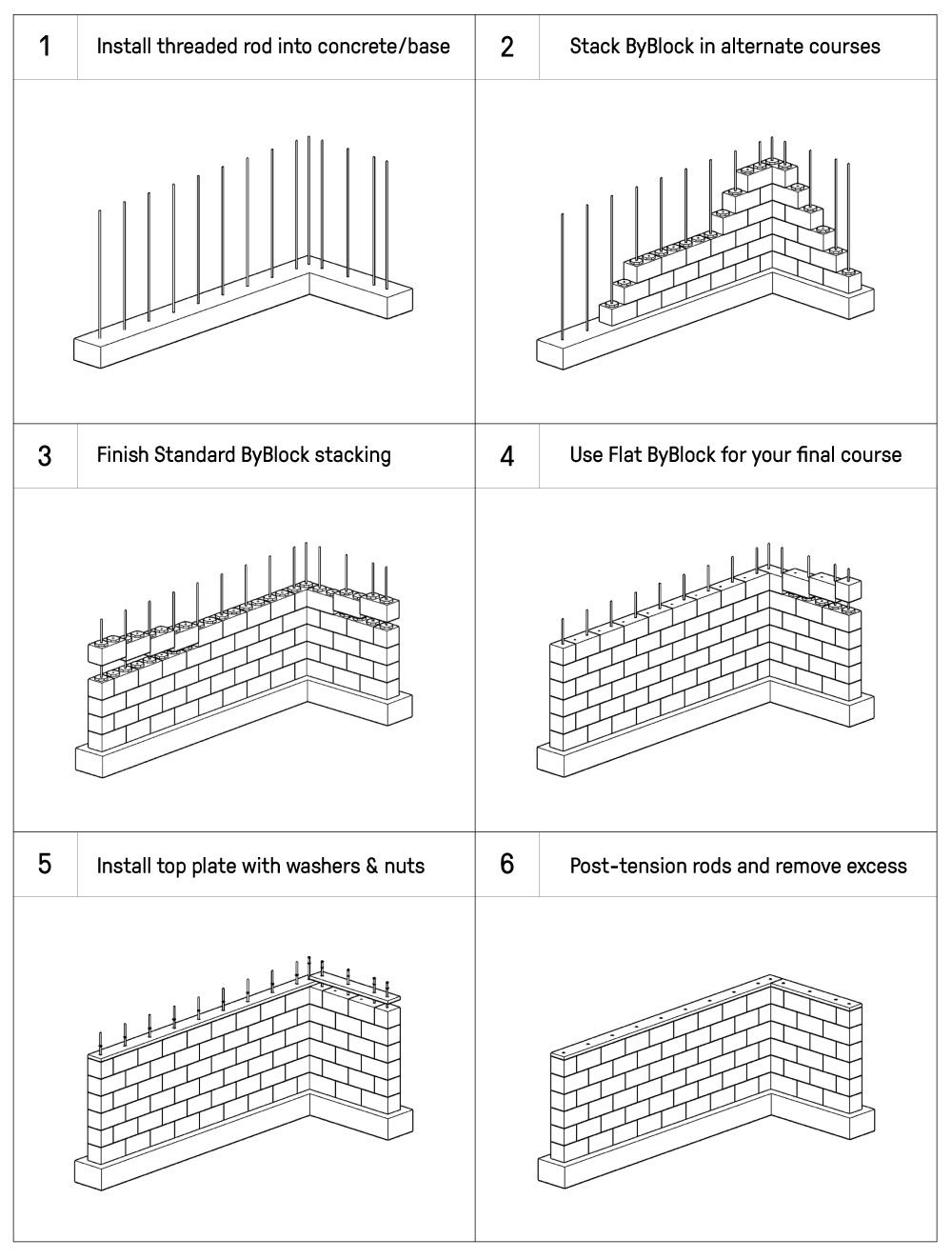

How to Build with ByBlock

Building with ByBlock is fast and easy.

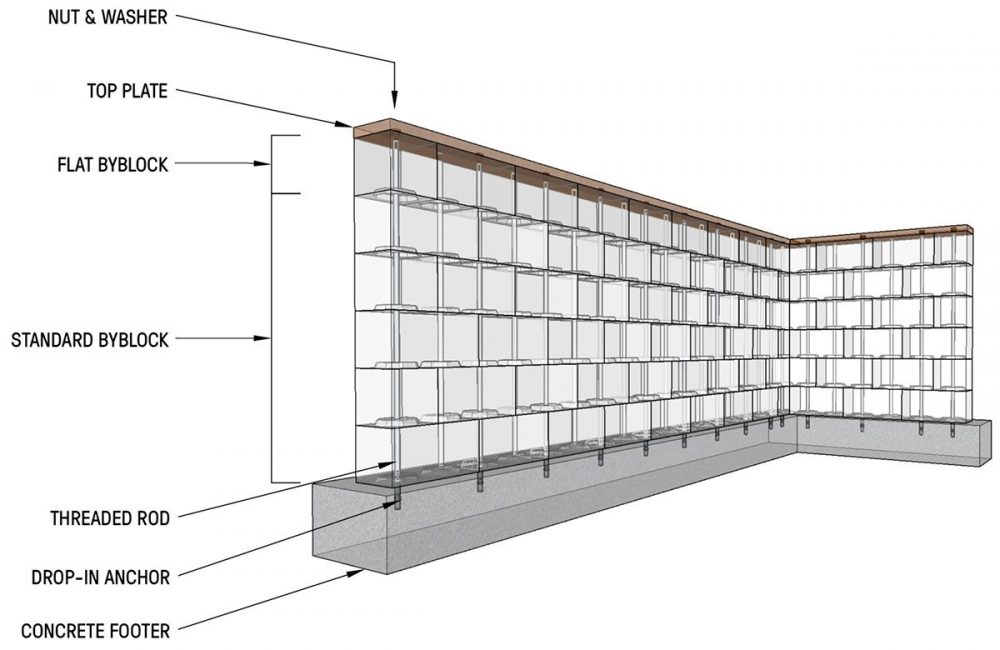

The primary materials required for ByBlock construction include the ByBlock itself, threaded rod, washers and nuts, lumber or steel top plates, base mounting hardware, and covering. That’s it! ByBlock does not require any additives or fillers, glues, or mortars. Instead, the rods are secured within your base and extend through each ByBlock with the pins and dimples locking together.

Your base material could be concrete/cement, lumber, or steel. With concrete, there are a few options for anchoring the metal rods: place rods in cement when it is poured, drill holes in concrete, and either install drop-in anchors or use epoxy. Using drop-in anchors afford us the quickest installation with the most precision.

Remember, when planning your project, you need at least one rod running through each ByBlock.

Once ByBlock stacking has been completed, a top plate is placed onto your final course and secured using standard washers and nuts. At this point, tightening the nuts (post-tension) will draw the ByBlock courses together and lock them tightly into position. This is where a ByBlock wall assembly gets its strength.

Then, once the nuts are tightened and the walls are compressed together and level, the excess rod can be cut back using a grinder or reciprocating saw.

Lastly, because ByBlock is designed to be covered and protected from the elements, the final step is to add a finish of your choice (stucco, sheetrock/drywall, plaster, siding, paneling or even specialized paints). If your outdoor project is designed to feature ByBlock visually, a clear UV coating will need to be applied. UV protective products are readily available in the market today.

Done! Now you have a perfectly-functioning, durable structure made almost entirely out of post-consumer plastic.

During the construction process, we recommend cutting any half ByBlock that you need in advance to keep the project running smoothly. ByBlock can be cut using standard power tools such as a table saw, reciprocating saw, band saw, or even a chainsaw.

ByBlock General Wall Build Diagram using a concrete base, Standard ByBlock (Pins and Dimples), Flat ByBlock (flat top with Dimples), and a timber top plate.

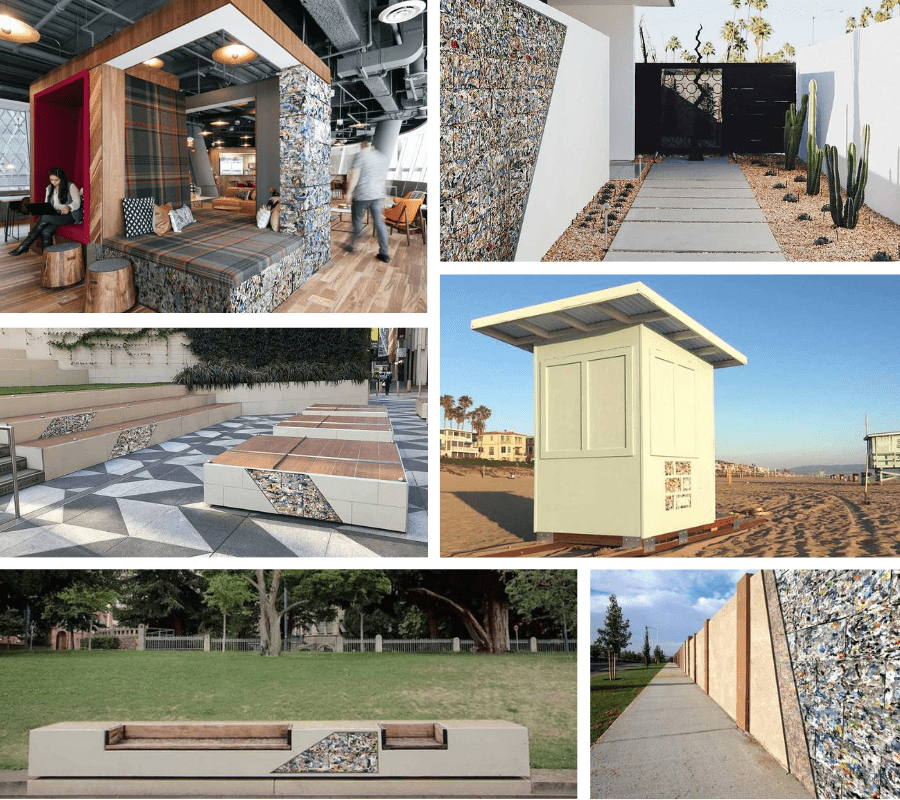

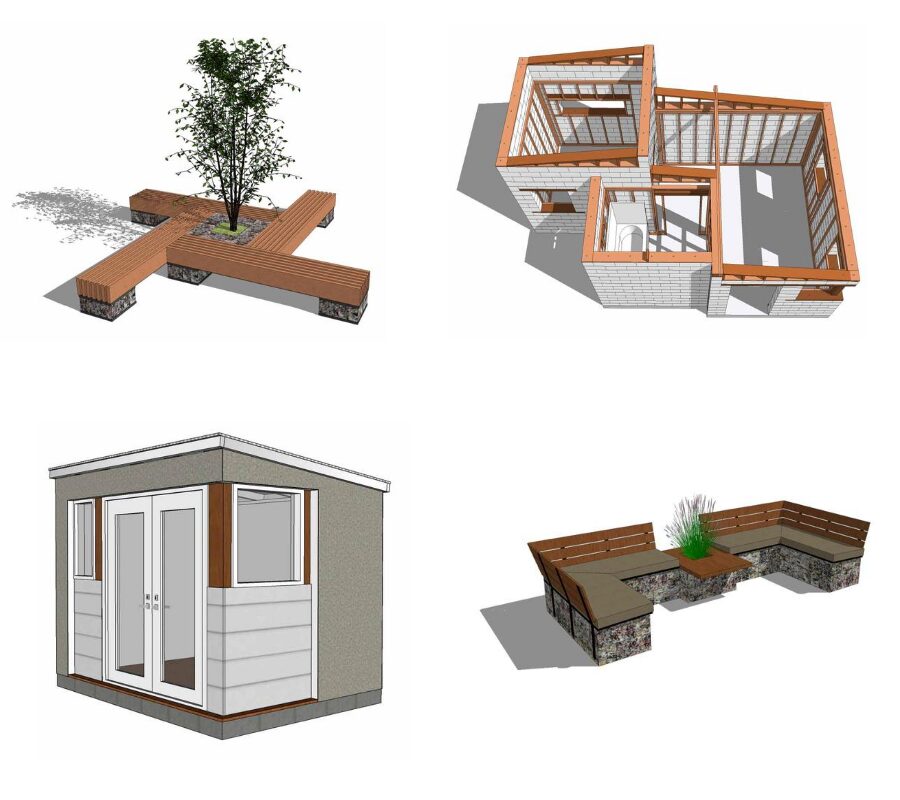

What Can You Build?

ByBlock is designed for a wide variety of residential, commercial, and institutional projects. From landscaping and gardening, to flooring and fencing, to small buildings like sheds or offices, ByBlock truly does it all. Tap into your construction imagination and ByBlock can likely accommodate.

Thus far, ByFusion has completed two official pilot projects: an athletic pavilion on the sports field of Island School in Lihue, Kauai and a lifeguard tower on Bruce’s Beach in Manhattan Beach, California. In both cases, the community was elated with the quality of the structures and their waste diversion function, while the construction team raved about ByBlock’s simple assembly — inspiring ideas for additional projects in both locations.

Below are some images to inspire your next project. We encourage you to stretch your imagination and think of ways to use ByBlock that even ByFusion hasn’t thought of!

What Will You Build?

ByFusion has created an innovative solution to the global plastic waste crisis. ByFusion offers communities the power to not only decrease plastic waste in their own backyard, but turn this plastic waste into buildings and infrastructure. Even at the DIY home project level, ByBlock turns the average building project into something special.

ByFusion is committed to recycling 100 million tons of plastic by 2030. With each ByBlock repurposing 22 lbs of post-consumer plastic, ByFusion and communities around the world can co-create a future with less plastic waste and more environmentally-superior buildings.

ByBlock will be available for pre-order starting October 2020, subscribe here if you’re interested in the pre-order process.

Connect with the ByFusion Community: