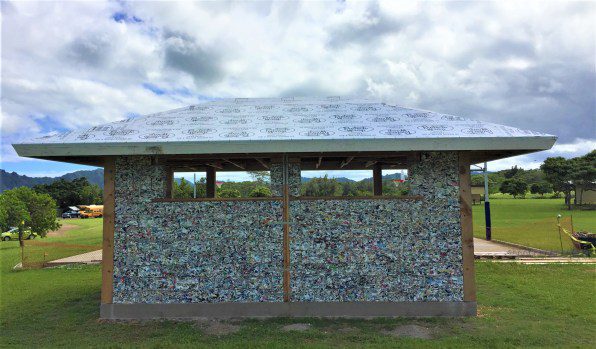

The pilot project is led by the Hefty® EnergyBag® program and Dow, in collaboration with ByFusion, and offers an exciting and sustainable way to reuse hard-to-recycle plastic waste

LAKE FOREST, Ill., February 16, 2022 – Today, Reynolds Consumer Products and Dow announced the Hefty® EnergyBag® program is collaborating with ByFusion on a pilot project to introduce a new creative use for hard-to-recycle plastic items collected by local participants in the Greater Boise area. The ByFusion pilot project demonstrates how communities of all sizes can innovate solutions to environmental challenges and put their hard-to-recycle plastic waste to good use by converting it into a building material that supports their community. The current project leverages public-private partnerships and will divert up to 72 tons of hard-to-recycle plastics from the Ada County Hidden Hollow landfill, which helps decrease its environmental impact.

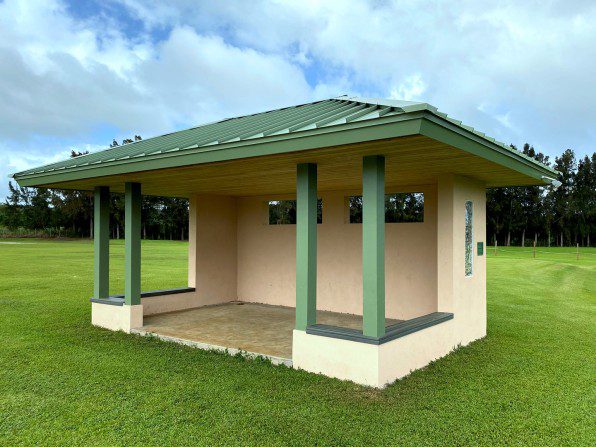

The ByFusion pilot project will convert the hard-to-recycle plastics collected by the Hefty® EnergyBag® program into ByBlocks, the first-ever construction-grade block made from collected, previously unrecycled plastics. ByFusion’s proprietary, no-emission process creates ByBlocks made entirely from plastic waste, containing no chemicals, additives or fillers. The fusion process does not require traditional sorting, cleaning or pre-processing. The ByBlocks can build a range of structures, including benches, bus shelters and much more. The first ByBlock application planned for the Greater Boise area is a large bench in Manitou Park. Additional projects are planned over the next few months, including a park bench in Garden City and other benches and kiosks within the area.

“I was excited when I learned about the ByFusion pilot project in the Greater Boise area because not only is it a beneficial way to use hard-to-recycle plastics, but the plastic collected comes from local residents who use the Hefty® EnergyBag® program,” said Jennifer Ellis, Greater Boise community sustainability advocate. “From material collection to a finished post-consumer recycled-content product, this really makes an impact on the distance the material has traveled in the past and the endgame for the material. I appreciate that the Hefty® EnergyBag® program encourages people to find alternatives to simply throwing that plastic away. While the first priority should always be to refuse, reduce or reuse unnecessary plastic waste, having the program available to collect the hard-to-recycle plastics is a welcomed diversion from landfill. It’s because of us, the citizens of these communities, that this project is even possible. I am looking forward to visiting Manitou Park, enjoying the park bench and talking about it with my fellow Boiseans.”

The Hefty® EnergyBag® team is also taking the opportunity to determine the environmental impact of the ByFusion pilot project from beginning to end, through a life cycle assessment. Having a better understanding of the full global warming impact of the material used in ByBlocks in comparison to other usages of the collected materials will inform how the Hefty® EnergyBag® program and ByFusion may work together in the future.

“We are always exploring new end-usage opportunities for the hard-to-recycle plastic collected by the Hefty®® EnergyBag® program, including the potential to expand beyond plastic as an energy source, which is why participating in the ByFusion pilot project is such an exciting moment for the Hefty® EnergyBag® program,” said Lisa Burns, Senior Vice President, Marketing, Reynolds Consumer Products. “Seeing the transformation of these challenging plastics into this impressive park bench is a testament to what is possible and what the future could hold for the Hefty® EnergyBag® program.”

“ByFusion is excited to be part of this collaboration with Dow and the Hefty® EnergyBag® program that collectively empowers the residents of the Greater Boise area to take control of their plastic waste and use it to support their growing, environmentally-conscious community,” said Heidi Kujawa, CEO, ByFusion. “We are confident that the area’s implementation of ByBlocks will show other cities how they can repurpose their plastic waste and transform it into an alternative building material that helps support their infrastructure needs, instead of being an ongoing burden.”

The ByFusion pilot project was developed in collaboration with Dow’s Business Impact Fund, which is a competitive grant program. The Hefty® EnergyBag® program, which is conducted in partnership with Dow, was already in place when the ByFusion pilot project launched. The program was first adopted by the City of Boise in 2018, and other local communities within Ada County soon followed.

“Since the Business Impact Fund was introduced in 2016, it has awarded over $5 million for 35 projects around the globe. Every project, including the ByFusion pilot, has the potential to have a tremendous and positive impact on the local community,” said Julie Zaniewski, Dow’s North American Sustainability Director for Packaging & Specialty Plastics. “Dow and the Hefty® EnergyBag® team, along with ByFusion and the Greater Boise area, are committed to this project as an innovative way of reducing the amount of plastic that is otherwise sent to landfills. It is our collective hope that other cities and communities, beyond Boise, will be inspired to think creatively about new uses for this valuable material.”

Developed with Dow and other program supporters, the Hefty® EnergyBag® program is a hard-to-recycle plastics collection program that offers eligible residents in the Greater Boise area a convenient way to divert hard-to-recycle plastics from the landfill (learn more about the program here and check here for a list of the participating communities in Idaho). The Hefty® EnergyBag® orange bags can be purchased at select local retailers or online. Once the orange bag is filled with hard-to-recycle plastics, residents simply place it in the same bin or cart as their traditional recycling. The regular recycling truck takes the orange bags along with normal, loose recyclables, and the recycling center then separates these bags from other materials and sends them to facilities that use the hard-to-recycle plastics as valuable resources.

Through April 2021, the Hefty® EnergyBag® program has diverted over 1,300 tons of hard-to-recycle plastics from landfills and is currently active in communities in Nebraska and Idaho, along with five counties in the metro Atlanta, Georgia, area.

About Reynolds Consumer Products

Reynolds Consumer Products (REYN: Nasdaq) is a leading provider of household products that simplify daily life so you can enjoy what matters most. Our Reynolds® and Hefty® brand products help make mealtime easier with preparation, cooking, cleanup, and storage solutions. For more information, visit ReynoldsConsumerProducts.com and HeftyEnergyBag.com.

About Dow

Dow (NYSE: DOW) combines global breadth, asset integration and scale, focused innovation and leading business positions to achieve profitable growth. The Company’s ambition is to become the most innovative, customer centric, inclusive and sustainable materials science company, with a purpose to deliver a sustainable future for the world through our materials science expertise and collaboration with our partners. Dow’s portfolio of plastics, industrial intermediates, coatings and silicones businesses delivers a broad range of differentiated science-based products and solutions for its customers in high-growth market segments, such as packaging, infrastructure, mobility and consumer care. Dow operates 106 manufacturing sites in 31 countries and employs approximately 35,700 people. Dow delivered sales of approximately $39 billion in 2020. References to Dow or the Company mean Dow Inc. and its subsidiaries. For more information, please visit www.dow.com or follow @DowNewsroom on Twitter.

About ByFusion

ByFusion® is an innovative manufacturing company committed to protecting the environment and giving a second life to plastic waste by reshaping its future. A certified B Corporation and an essential cog in the wheel of a circular economy, ByFusion has a patented process that converts all types of plastic waste, including marine debris, into a building material called ByBlock®—the first-ever construction-grade block made from unrecyclable plastic. ByFusion’s solution enables communities, corporations and governments to realize a cleaner world while creating jobs, improving infrastructure and revitalizing neighborhoods everywhere. For more information, please visit www.byfusion.com/or follow @ByFusion on Instagram and Twitter.

Media Contact:

HeftyEnergyBagPress@reynoldsbrands.com

Media@ByFusion.com