The global plastic recycling industry has been in the spotlight over the last few years due to increasing awareness about the abundant plastic waste problem, carbon emissions issue and the need to reduce them both. This coupled with the recent China ban, which took effect in December 2017, has accelerated the need for new and different solutions to plastic waste. ByFusion is offering such a solution through it’s patented process that converts all types of plastic waste into an advanced building material.

Ground Zero for Plastic Recycling and Diversion– Materials Recovery Facilities (MRF’s) + ByFusion

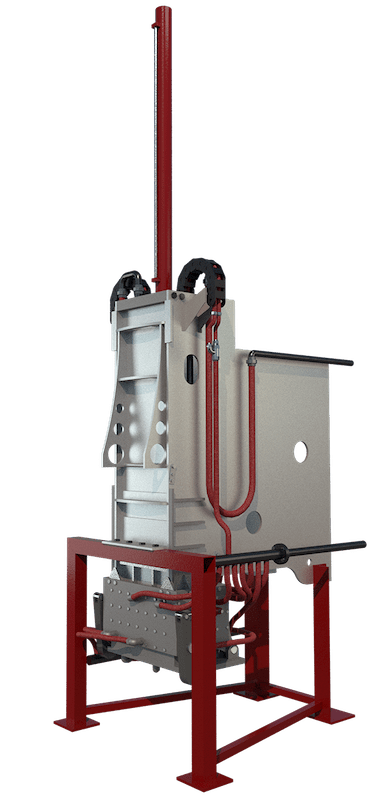

Meet the Blocker and ByBlock

We call the Blocker the “ultimate environmental diversion solution”. To explain it simply, this machine takes plastic waste and converts it into construction-grade building blocks, ByBlocks. The Blocker is designed to be placed and operated in MRFs and plastic producing facilities as their purpose is to “maximize the quantity of recyclables processed, while producing materials that will generate the highest possible revenues in the market.”² Because copious amounts of plastic are being sent to MRFs already, they have the ability to significantly increase the plastic being processed by allocating unrecyclable plastics to the Blocker which then produces the ByBlock (without the costs of sorting and prewashing), a product able to generate increased revenue.

Blockers– Modular and Scalable

The Blocker comes in two primary sizes– Community and Industrial. The Community Blocker is geared toward small recycling operations, community projects, disaster relief/clean-up efforts and mobility, with the capacity to process up to 30 tons of plastic per month. The Industrial Blocker, however, is intended for large scale, industrial installations and can be scaled up or down to meet venue space limitations and almost any plastic volume requirement, processing 90+ tons per month.

Blocker– How it Works

The innovative technology which makes up the Blocker, converts any type of plastic, including plastic numbered 3-7, which are among the most difficult to recycle, into a useful, marketable construction-grade building block called ByBlock.

ByBlocks in a nutshell– or plastic clam shell as it were:

- Dimensions: 16″ x 8″ x 8″ / 40cm x 20cm x 20cm

- Weight: 22lbs / 10kg

- Can be customized to specific densities

- Doesn’t crack or crumble like concrete blocks

- Requires no glue or adhesives

- 41% fewer greenhouse gas emissions than concrete blocks

Let’s Build with the ByBlock

- Landscaping & Walling: Privacy, sound and retaining

- Infrastructure & Utility: Sound walls, kiosks, storage sheds, security

- Parks & Recreation: Pavilions, benches, planters, open space projects

- Commercial, Residential & Consumer: Accent walls, furniture, modular structures such as sheds, detached office spaces and various other residential projects

The ByBlock can be utilized to improve infrastructure by anyone, eliminating the need for highly skilled, in-demand construction tradesmen/women, opening up a whole new labor field to support construction needs. However, as highlighted above, ByFusion’s business plan is not limited to consumer building needs. ByFusion aims to partner with materials recovery facilities, corporations, waste management companies, and governments to install Blockers on site, allowing them to effectively process excess plastic and create an additional revenue stream through the budding ByBlock market.

Why Choose ByFusion?

Below are four reasons for MRFs to incorporate a ByFusion Blocker into their technology stack:

ByFusion Increases Revenue Opportunities and/or Lowers Costs:

ByFusion allows MRFs to create saleable construction-grade building products, ByBlock, thus creating a new revenue stream and decreasing the overall cost associated with currently sending this plastic to landfill and paying tipping fees.

Decreases Contamination and Increases Diversion:

Contamination in recycling is a major issue for all MRFs. ByFusion creates systemic incentive to sort what is currently considered a contaminant, bound for the landfill and recovers it as valuable material for construction-grade building blocks.

ByFusion’s Blockers Are Modular:

MRFs come in all shapes and sizes and thus require adaptable, modular technology to custom fit their unique waste volumes and space requirements. Similarly, Blockers are designed to support small facilities and waste streams or scaled to meet the needs of large volumes and expansive facilities.

Meeting Community’s Environmental Goals:

MRFs have the challenging position of meeting regional or statewide waste diversion requirements, yet are subject to the vagaries of national and international waste markets. ByFusion offers MRFs something no other plastic recovery technology does– the opportunity to locally divert a community’s plastic waste and turn it into a product for building local facilities and structures– true local diversion and local recycling.

Our Dedication to Bettering the Environment and Communities Across the Globe

ByFusion is focused on creating a partner network that solves the global plastic crisis by empowering communities to block their waste in place while leveraging it to solve increasing challenges around job creation, affordable housing and crumbling infrastructure, the support of aggressive waste reduction goals, and supply the local market with an incredibly cost effective, 100% recycled advanced building material. ByFusion is recognized by the Alliance to End Plastic Waste, New York Times, Fast Company’s World Changing Ideas (2019), US Green Building Council Net Zero Accelerator (2019), B Corps Best for the World (2019), 1% for the Planet’s Innovation of the Year (2018) and Waste Dive’s ‘Most Disruptive Innovation of the Year’ Award (2016). As a company, we are dedicated to the healing of Earth and truly believe our patented process is a key component to regenerating the planet and reshaping our relationship to plastic.